Published on May 6, 2021

Hatchery Management Techniques for Optimum Flock Performance

A recent article in Poultry Health Today discussed the importance of incubation. By focusing on a few key areas, hatchery managers can ensure that each poult can get off to a great start.

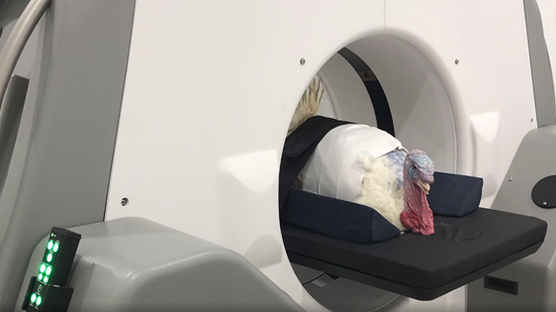

In the realm of commercial turkey production, effective hatchery management is paramount.

Proper incubation and early poult care lays the foundation for robust flock performance. This impacts growth rates, feed efficiency, and overall health.

In this article we mention several essential practices for hatching turkey eggs, rearing turkey poults, and optimizing turkey genetics to ensure success in turkey farming.

The Critical Role of Hatchery Management in Turkey Production

Hatchery conditions significantly influence the viability and uniformity of turkey poults. Precise control over temperature and humidity level during hatching turkey eggs incubator usage ensures proper yolk sac absorption, leading to stronger, more uniform poults ready for rearing.

Optimizing Incubation for Turkey Eggs

Temperature to Hatch Turkey Eggs

- From day 1 to 25 of incubation, maintaining an eggshell temperature between 99.4°F and 100°F (37.4°C to 37.7°C) is crucial. This range supports optimal embryonic development post turkey eggs hatching, leading to healthy turkey chicks.

Adjusting Incubation for Egg Variability

Not all turkey hatching eggs are identical. Eggs from older turkey hens often have larger yolks, generating more heat. Adjusting incubation temperature profiles accordingly ensures consistent development across all eggs.

Importance of Hatch Window Monitoring

Monitoring the hatch window is vital. Ideally, 1% to 3% of turkey poults should hatch 36 hours before the scheduled pull time. Exceeding 25% may indicate dehydration and impact turkey flock uniformity.

Calculating Poult Yield for Quality Assessment

A newly hatched baby turkey should weigh approximately 67% to 68% of the original egg weight. Deviations may signal issues in incubation timing or temperature, affecting poult quality.

Enhancing Poult Survival Post-Hatch

Maintaining Optimal Internal Temperatures

Post-hatch, maintaining poult internal temperatures between 103°F and 104°F (39.4°C to 40°C) is essential. This range encourages activity, feeding, and hydration, promoting healthy development.

Importance of Feed and Water Post Placement

Providing immediate access to food and water after placement ensures your turkeys develop robust digestive and immune systems, setting the stage for strong performance throughout their lifecycle.

Best Practices for Rearing Turkey Poults

Brooding Environment and Temperature Control

Creating a conducive brooding environment with appropriate temperature control is vital. Consistent warmth and protection from drafts support poult comfort and growth.

Biosecurity Measures in Poultry Farming

Strict biosecurity protocols prevent disease introduction and spread. Regular sanitation, controlled access, and monitoring are key components of effective farm management to raise turkeys.

Leveraging Turkey Genetics for Improved Flock Performance

Understanding Turkeys and Their Traits

Selecting the right turkey product influences growth rates, feed conversion, and adaptability. Hybrid Turkeys offers advanced turkey genetics, focusing on traits like disease resistance and feed efficiency, contributing to improved flock performance. The Hybrid Converter turkey is renowned for its total system profitability, making it a preferred choice in commercial turkey production.

Resources for Turkey Farmers and Hatchery Managers

For further insights and support, explore the following resources: Hybrid Turkeys Hatchery Management Resources