Published on Nov. 2, 2020

Poultry house ventilation for cold weather

As the season changes, cold weather ventilation is a priority to ensure the well-being and performance of your flock. This article explains how to establish and maintain an optimal environment inside your poultry house using the concepts of negative pressure ventilation.

Start with a tight house

The foundation of minimum winter ventilation begins by having a tight house. Then, with the creation of proper airflow and direction, we can use fans as a water pump to remove moisture.

To test the tightness of a house, you need to first close all openings, which include curtains, inlets, and doors. Next, turn on minimum fans to as close as possible to 1 cfm per square foot of your barn. Then measure the static pressure with a magnehelic. The recommended ranges are a minimum of 0.15” static pressure (SP) for older or renovated houses through 0.20” SP or greater in new houses. The tighter the house, the more efficient it will function. If static pressure is outside these recommended ranges, common problem areas are as follows:

- Unsealed Curtains: Attach curtain seals to the top of the curtains to prevent air leakage. You can also consider fastening the bottom of the curtain to the barn to avoid any additional air leakage.

- Unused and dirty fans: Remove built-up dust and dirt that may be preventing fans from closing properly. Consider covering fans that are not in use during cold weather with plastic, insulation board, or plywood to eliminate unwanted drafts.

- Improperly sealed end doors: Thoroughly weatherstrip the perimeter of end doors to prevent air leakage. This is one of the most overlooked areas, even in newer barns!

Conditioning incoming cold air

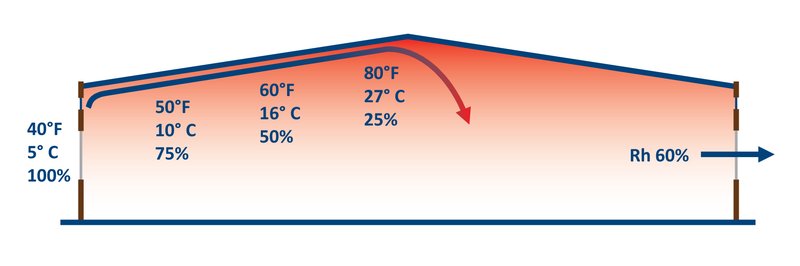

To create both air pressure and air volume that project and condition the incoming air, start by having the correct number of fans and inlets. These numbers depend on the size of a house. The objective is to bring in cold air from the outside and have it travel along the ceiling to gradually warm and increase its water holding capacity. When done correctly, you will find that for approximately every 11°C we warm the incoming outside air, we decrease the humidity by half.

Let us consider an example where the outdoor temperature is 5°C with 100% relative humidity (RH). If we warm the air as it comes into the barn to 16°C, then the relative humidity drops to 50%. If we can continue to warm to 27°C, then the relative humidity drops to 25%.

The idea behind this conditioning of incoming air is that you use fans to create a water pump. For example, if we take a house with an internal temperature of 27°C and 50% RH, using a 10,000 cfm fan for 30 seconds on out of 5 minutes, you can remove 2.8 gallons (10.6 L) of water per hour. In a 24-hour period that equals 67 gallons (254 L). Our goal is to keep relative humidity below 60%. By adjusting the amount of fan run time, you can regulate the amount of moisture inside the house and better control the environment.

By having the correct number of fans and inlets you can create the appropriate airflow. To calculate the correct number of inlets for your desired fan capacity please contact Hybrid Turkeys to obtain a copy of their ventilation calculator.

A good rule of thumb is for every 1 point of static pressure, air can be thrown 2-2.5’ (0.6-0.75m). Our goal is to get the air as close to the middle of the house as possible. Depending on the width of the house, the range can be from 0.09-0.12” SP to achieve our airflow goals.

Smoke emitters are a great tool, depending on the style and placement of inlets, to fine-tune the amount of inlet opening and air direction. Circulation fans are another great tool to ensure optimal conditions in a barn. Use of circulation fans help to mix cold and warm air together to reduce humidity and improve litter conditions. They are also a great tool to help prevent drafts in loose houses with poor air direction.

Conclusions

Negative pressure ventilation plays a key role in establishing a comfortable environment for your flock to thrive, especially during cold weather. In addition to improving environmental conditions, this method of ventilation reduces drafts and prevents air leakage, to allow for more efficient use of fuel and lower operation costs. Effective removal of moisture from a barn results in drier litter, lower levels of ammonia and lower levels of other gases in the air, such as CO or CO2 .

This article is based on a presentation given by William Alexander, during the virtual Poultry Service Industry Workshop on October 7, 2020. Contact us to learn more.