Water sanitation programs

Clean sanitized water is one of the most critical, but unfortunately often overlooked, elements in allowing a flock to perform to its full potential. Clean water reduces stress on the animals and helps to prevent common health issues such as Bordetella, E.coli, and salmonella.

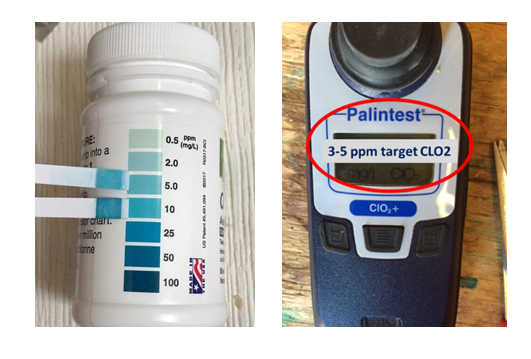

The three most common sanitation systems are chlorine dioxide, chlorine with acidification and hydrogen peroxide. Each have their own positive and negative aspects. To make sure the sanitizer is working properly, it is recommended to take water samples routinely (at least once per week). Simply go to the end of your line and get a clean, non-contaminated water sample with your sanitizer present in the water system.

General sanitation recommendations

Drinkers

- All bell-type drinkers must be washed with a disinfection solution at least three times per week.

- Take apart the drinker and wash the bell and bowl with a brush or scrub pad.

- Water should be dumped into a bucket and removed from the barn.

- Disinfect nipple drinkers between flocks.

Water lines

- In between flocks, clean lines as soon as birds are moved out and 24-48 hours before placement.

- Make sure you use the product at the necessary rate through a pump or adjustable medicator.

- Let the product set for at least 24 hours and then properly flush when done.

- Flush water lines after placement as follows:

- First 3 weeks: 4 times per week for 10-15 minutes .

- Week 4 onwards: 2 times per week for 10-15 minutes.

3 Types of water sanitation

1) Chlorine dioxide

Pros

- Very effective when used with challenged water (i.e. well water)

- Can eliminate biofilm

- Can eliminate odors from high sulfur/mineral water

- OMRI (Organic Materials Review Institute) approved and can be used in an organic system.

Cons

- On site activation is time consuming and must be completed in a well-ventilated area

- A more expensive system

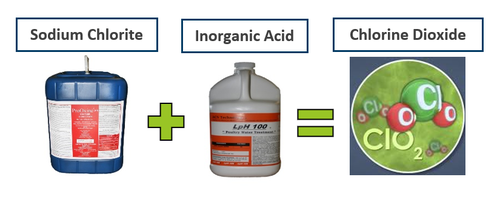

Chlorine dioxide is a strong sanitizer made up of sodium chlorite and inorganic acid. It is an unstable form of chlorine that rapidly breaks down into harmless water and salt. The conversion from chlorite to is achieved by mixing the chlorite solution with citric acid, transforming the chlorite to chlorine dioxide (CL02). Simply mixing the two components together without adequate “dwell time” for activation results in little to no CLO2 being generated.

Delivery Methods

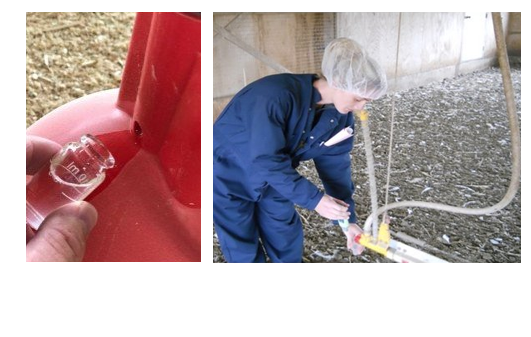

AANE (Automatic Activation No Electric) system

The best way to activate chlorite is by having a pump system such as an AANE system that automatically mixes the acid and chlorite solution. This kind of system gives the solution appropriate time to activate and introduces the chlorine dioxide into the water system at your desired rate. When using a pump system use, between 1 and 5 ppm. The greater the health challenge, the higher ppm you want to use.

Manual

Alternatively, you can also mix the acid and chlorite solution manually into a separate bucket. Once you achieve activation you can then administer the product by mixing the desired rate into a stock solution and inject the product through a medicator or inject the activated solution through a pump. When using a 1:128 medicator mix 2 to 3 ounces of chlorine dioxide (5%) per gallon of stock solution. 5% chlorine dioxide products are more cost effective and overall work better than the 2% chlorine dioxide products. Activated product needs to be kept in a well-covered container to hold efficacy and the product should be covered up once initial activation is complete. Activated solution in a well-covered container will last 7 to 10 days.

Recommended values

- When activated with contact time, CL02 creates two items: free chlorine, which kills pathogens and chlorine dioxide, which removes biofilm. Levels of total chlorine should be 6-10 ppm and free chlorine at 3-5 ppm.

2) Chlorine with acidification

Pros

- Cost effective option

- Effective when used with less challenged water

Cons

- Not as effective in the presence of organic matter – cannot remove biofilm

- Corrosive to equipment when overused

Chlorine with acidification is a system that destroys organisms in the water using Hypochlorus acid (HOCI) and Hypochlorite ion (OCI). You must use two different pump systems with using both chlorine and acidification: one to pump in the acid and then one to pump in the chlorine. You should never mix the products together in the same open tank.

Recommended values

- ORP ≥ 750mV

- Total chlorine = 3-5ppm

- pH levels = 5.5 – 6.5

When using chlorine with acidification, it is important to measure ORP levels using the steps below.

Oxidation reduction potential (ORP)

Oxidation reduction potential (ORP) measures the oxidation level in the water in millivolts (mV). This value reflects the activity of the water sanitizer rather than its concentration level (ppm). Achieving the correct level of 750mV will deliver clean, sanitized water to your flock.

Download the ORP quick reference info sheet

How to measure:

- An ORP probe is a millivolt meter measuring the voltage across a circuit formed by a reference electrode constructed of silver wire (in effect, the negative pole of the circuit), and a measuring electrode constructed of a platinum band (the positive pole), with the water in between.

- Use a handheld meter by placing the meter probe into the water and then observe the display.

- Measure the ORP level at multiple points to ensure the cleaning agent is running through the whole system.

3) Hydrogen peroxide

Pros

- Very powerful oxidizer

- Non corrosive to your equipment

- Can be ready to use (no mixing required)

Cons

- Must be very carefully handled for safety reasons

- Cannot be used in combination with chlorine

- Must be stored properly away from sunlight

Hydrogen peroxide products can also be a very effective tool to sanitize your water system. Like chlorine dioxide, hydrogen peroxide is a powerful oxidizer up to two times more powerful than chlorine.

Instructions

If you are mixing product into a stock solution and injecting the peroxide through a 1:128 medicator, 3 to 4 ounces per gallon of 50% peroxide can generally be used to achieve 25 to 50 ppm. If you are using a pump system, simply adjust your equipment to inject 25 to 50 ppm of product. The important thing to remember about hydrogen peroxide products is that they should only be run for 4 to 5 consecutive days and then rotate back to your chlorine or sodium chlorite product for 4 to 5 days.

Recommended values

- 25-50 ppm of available peroxide. In certain health challenged situations, 100 ppm can be used, but this is considered a treatment level and should only be used for a shorter duration.